E-mail

E-mail- service@minespareparts.com

Suitable for metallurgy, construction, road construction, chemistry and silicate industry raw materials crushing machinery, is the preferred intermediate crushing.Cone crusher crushing ratio, high efficiency, low energy consumption, uniform particle size, suitable for medium and fine crushing all kinds of ore, rock.

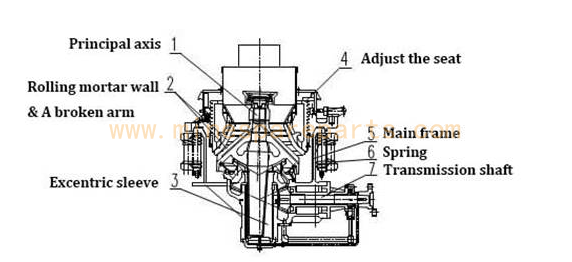

In the working process of the cone crusher, the motor drives the eccentric sleeve to rotate through the transmission device, and the moving cone rotates and swings under the forced action of the eccentric sleeve. The section of the moving cone close to the static cone becomes the crushing chamber, and the material is crushed by the multiple extrusion and impact of the moving cone and the static cone.When the moving cone leaves the section, the material that has been broken to the required size falls under the action of its own gravity and is discharged from the bottom of the cone. The performance characteristics

1. Higher production capacity and better quality

2. The shutdown time is greatly reduced due to the safety device.

3. The body is of cast steel structure, and reinforced bars are set in the heavy duty parts.

4. Including the regulator, can quickly adjust the size of the crushing material size.

5. Provide spring type protection device.

6. With a complete lubrication system, when the temperature is too high or the flow rate is too slow will automatically close.

7. Good sealing performance of internal structure can effectively protect the equipment from dust and other small particles.

8. Long service life and strong applicability.

| Model | Cavity Type |

Max.Feeding Size (mn) |

Min. Discharging Port Size (mm) |

Motor Power (kW) |

Closed Edge Material Discharging Port(Mm)Output(TPH) | Weight (kg) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 10 | 13 | 16 | 19 | 22 | 25 | 38 | 51 | 64 | ||||||

| VSC24 | C | 95 | 10 | 37-45 | 20 | 25 | 30 | 35 | 45 | 50 | 75 | 5300 | |||

| M | 72 | 6 | 37-45 | 18 | 20 | 25 | 30 | 35 | 40 | 45 | 60 | 5300 | |||

| VSC40 | C | 160 | 13 | 90-110 | 80 | 100 | 135 | 150 | 175 | 235 | 10800 | ||||

| M | 115 | 10 | 90-110 | 65 | 75 | 90 | 120 | 135 | 150 | 10800 | |||||

| F | 80 | 8 | 90-110 | 50 | 55 | 65 | 70 | 95 | 10510 | ||||||

| EF | 50 | 6 | 90-110 | 52 | 62 | 72 | 78 | 102 | 10510 | ||||||

| VSC45 | C | 180 | 13 | 110-132 | 115 | 135 | 150 | 180 | 200 | 260 | 15500 | ||||

| M | 130 | 10 | 110-132 | 100 | 110 | 120 | 135 | 165 | 175 | 15500 | |||||

| F | 90 | 10 | 110-132 | 80 | 105 | 110 | 140 | 15500 | |||||||

| EF | 60 | 6 | 110-132 | 60 | 74 | 105 | 110 | 130 | 15500 | ||||||

| VSC51 | C | 200 | 16 | 132-160 | 150 | 180 | 200 | 230 | 310 | 390 | 22300 | ||||

| M | 150 | 13 | 132-160 | 115 | 140 | 160 | 190 | 210 | 22300 | ||||||

| F | 102 | 10 | 132-160 | 90 | 115 | 145 | 160 | 22300 | |||||||

| EF | 70 | 8 | 132-160 | 88 | 110 | 135 | 155 | 22300 | |||||||

| VSC54 | C | 215 | 19 | 185-220 | 200 | 220 | 260 | 330 | 420 | 26300 | |||||

| M | 160 | 16 | 185-220 | 155 | 180 | 200 | 220 | 26300 | |||||||

| F | 115 | 13 | 185-220 | 150 | 190 | 210 | 230 | 26300 | |||||||

| EF | 76 | 8 | 185-220 | 122 | 148 | 185 | 200 | 26300 | |||||||

| VSC60 | C | 235 | 22 | 220-250 | 240 | 265 | 300 | 400 | 510 | 570 | 37750 | ||||

| M | 175 | 19 | 220-250 | 215 | 240 | 265 | 320 | 37750 | |||||||

| F | 130 | 13 | 220-250 | 180 | 210 | 235 | 255 | 275 | 37750 | ||||||

| EF | 90 | 10 | 220-250 | 148 | 178 | 220 | 265 | 37750 | |||||||

| VSC66 | C | 267 | 22 | 250-300 | 330 | 390 | 525 | 655 | 725 | 44300 | |||||

| M | 203 | 16 | 250-300 | 230 | 270 | 300 | 330 | 44300 | |||||||

| F | 140 | 13 | 250-300 | 185 | 225 | 265 | 340 | 44300 | |||||||

| EF | 95 | 10 | 250-300 | 180 | 220 | 260 | 335 | 44300 | |||||||

E-mail

E-mail